Reinforcement of Asphalt Concrete Mixture Using Polypropylene Fibers

2024-07-18 | volume 2 Issue 2 - Volume 2 | Research Articles | Mahmoud AbdullhAbstract

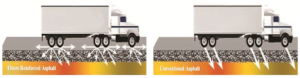

The performance of asphalt roads is affected by many factors such as temperature, water, loads and materials characteristics. These factors cause thermal cracking, permanent deformation (rutting) and fatigue distresses on asphalt concrete layers. In the last years, many researchers studied improving the performance of asphalt concrete by using polypropylene synthetic fibers (PPF). This paper describes a laboratory study on the mechanical characteristics of asphalt mixtures by reinforcing them with polypropylene fibers and improving their characteristics and durability. The physical characteristics of the asphalt binder (Penetration at 25°C, ductility, softening point) were carried out on reinforced and unreinforced asphalt binders with polypropylene fibers. It was found that the PPF reinforced asphalt can improve the consistency and characteristics of asphalt concrete. Asphalt concrete specimens were prepared with varying contents of polypropylene fibers (0%, 3%, 4%, 5% and 6% by weight of asphalt binder). In total, sixty specimens were prepared by using Marshall Mix design method (fifteen specimens were used to determine the optimum asphalt binder content and the remaining specimens were used to investigate the effect of reinforcing the asphalt mixtures with PPF. The mechanical characteristics of the reinforced asphalt mixtures with polypropylene fibers were compared with a reference asphalt mixture. The results show that increasing the amount of PPF in the asphalt mixtures led to increases in Marshall Stability and air void in the total mix, while the flow values decreased for all mixtures. It is noticed that the use of 5% PPF shows the highest stability value with flow and air voids values within specification limits [ASTM].

Keywords : Asphalt Binder, Asphalt Mixtures, Polypropylene Fibers (PPF), Stability.

Previous studies of reinforced asphalt concrete have focused on different types of fiber such as polypropylene, polyester, carbon and glass (5-8). Polypropylene fibers provide three-dimensional reinforcement of the concrete, making it tougher and more durable (9,10). The common forms of these fibers are smooth-monofilament and have triangular shape. Polypropylene fibers are widely used as reinforcing agents in rigid and asphalt pavement (11,12). Othman (2010) investigated the effect of polypropylene application method on long-term aging of hot mix asphalt (HMA). Three different polypropylene application methods were prepared for that purpose and a constant polypropylene content of 0.7% by weight of the total mix was adapted. The first mixture was prepared using polypropylene coated aggregate. The second mixture was prepared using the traditional wet process method, where polypropylene is blended with asphalt binder at high temperature. The third mixture was prepared using the dry method where polypropylene powder was added to the mineral aggregate prior to mixing it with asphalt. Testing procedures included the Marshall tests for aged and unaged mixtures, indirect tensile strength, fracture energy, and unconfined compressive strength. This paper concluded that the inclusion of polypropylene has significantly improved indirect tensile strength, fracture energy, and unconfined compressive strength. It was also concluded that samples prepared using polypropylene coating methods displayed the highest tensile strength and fracture energy under aged and unaged conditions (13). Tapkın et al. (2009) concluded that the most suitable polypropylene fibers can be used at a dosage of 0.3% by weight of the aggregates and increased the Marshall stability values by 20% and the life of the Polypropylene fibers modified asphalt specimens under repeated creep loading at different loading patterns by 5–12 times versus control specimens. It also indicated that the addition of polypropylene fibers improves the behavior of the specimens by increasing the life of samples under repeated creep testing (14). Ahmad et al. (2015) studied the behavior of Polypropylene fibers reinforced asphalt mixtures on fatigue performance. The results from this study show that the addition of polypropylene fibers improves the behavior of the specimens by increasing the life of samples under fatigue testing according to the test results, the addition of 1.5 % of polypropylene fibers prolongs the fatigue life by 113 % in terms of number of cycles, in comparison to plain asphalt concrete beam (15). Zachariah et al. (2018) evaluated the effect of Polypropylene fibers reinforcement on bituminous concrete using brick as aggregates (first class brick and over burnt bricks). Resilient modulus tests, moisture susceptibility test, creep tests and indirect tensile strength test were performed. The Marshall test and basic property tests were used to justify the performance of polypropylene modified bituminous mixes using bricks as aggregates. This study concluded that brick aggregates can be used in asphalt concrete for using as a surface course if asphalt is modified with polypropylene fibers, and the optimum polypropylene fibers content was found to be 2% of aggregate by weight for first class bricks (where resilient modulus increased by 162%) and 4% of aggregate by weight for over burnt bricks (where resilient modulus increased by 157%). The results indicated that polypropylene fibers addition enhances the characteristics of asphalt, helps in reducing the temperature susceptibility of the mix, and fulfills the minimum requirement of tensile strength ratio TSR (16). Li et al. (2024) analyzed the viscoelastic characteristics of asphalt binders reinforced with polypropylene fibers by using dynamic shear rheological (DSR) testing. The binders reinforced with fiber showed superior resistance to high temperatures and long-term deformation while being less sensitive to temperature and having a more significant elastic characterization (17). Whereas Jalota et al. (2023) improved the moisture resistance of flexible pavements by using polypropylene fibers measuring 6 mm in length and different dosages of liquid anti-stripping agents (18). Other researches evaluated the influence of polypropylene fiber on concrete and rigid pavements (19,20), while other studies focused on hybrid reinforcement to improving performance of asphalt concrete mixtures through their reinforcement with two or more types of fibers such as: polypropylene and glass fibers (21,22), polyester and polypropylene fibers (23), glass and carbon Fibers (24), polyolefin and aramid fibers (25) and Hybrid Fiber and Nano (26).

MATERIAL AND METHODS

Asphalt binder

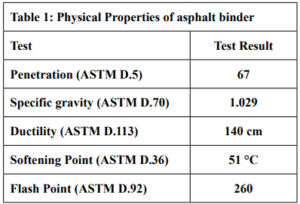

The Asphalt used in this study was a 60/70 penetration grade obtained from Homs Refinery Company. The Physical Characteristics of the Asphalt binder were tested according to standard specifications and are listed in Table 1. Aggregates

Aggregates

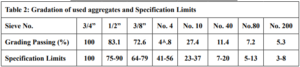

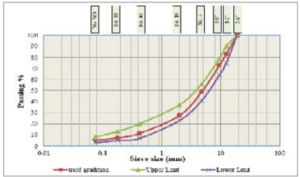

The coarse and fine aggregates were supplied from Hsia City. The gradation of the test specimens was performed in accordance with ASTM of surface course, Table 2 and Fig. 2 show the gradation of these aggregates. They were selected and incorporated in preparing all hot asphalt concrete mixes used in this study. The mechanical and physical characteristics of used aggregates have been tabulated in Table 3.

Experimental Methods

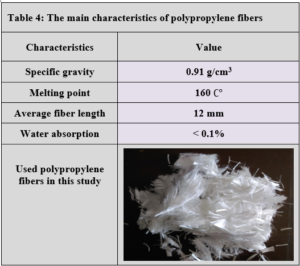

Polypropylene fibers were used in asphalt mixtures with different percentages (3, 4, 5 and 6%) by weight of the asphalt binder. polypropylene fibers were added to hot asphalt binder and mixed manually for five minutes (until the mix acquires uniformity). Then, the modified asphalt was mixed with aggregates. To determine the optimum asphalt content that would produce asphalt concrete mixtures, 15 samples were tested according to The Marshall test (ASTM.D 1559). The Marshall method is used for all mixtures. The optimum asphalt content was selected from figure. 3 as the average of the asphalt content for maximum density, maximum stability and 4% air voids. The optimum binder content was found to be 5% by weight of the total mix. All PPF modified specimens were prepared using constant asphalt binder content (5%) and produced at a mixing temperature of 160ºC.

RESULTS

Effect of Polypropylene fibers on the performance of the asphalt binder

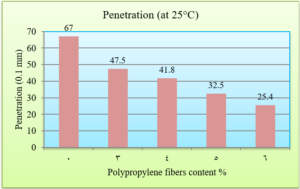

To determine the effect of Polypropylene fibers on the physical characteristics of the asphalt, penetration, softening point, and ductility tests were carried out on both reinforced and unreinforced asphalt binder with PPF. The penetration value determines the hardness of asphalt by measuring the depth (in tenths of a millimeter) to which a standard and loaded needle will vertically penetrate in 5 seconds a sample of asphalt maintained at a temperature of 25°C (ASTM D 5). The results of the penetration test are presented in Fig. 4.

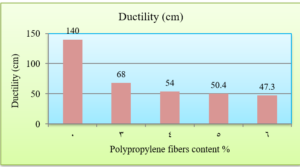

Ductility is the property of asphalt that permits it to undergo great deformation or elongation. It is defined as the distance in cm, to which a standard sample or briquette of the material will be elongated without breaking (ASTM D 113). Fig. 5 shows the change in the ductility of asphalt binder depending on the Polypropylene fiber content. As the Polypropylene content increases, the ductility values decrease.

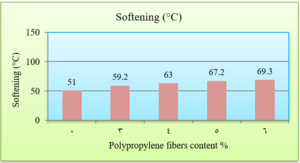

The softening point is determined as the temperature at which a sample of asphalt, subjected to a progressive increase in temperature and the weight of a steel sphere, reaches a consistence that leads to its flow through a ring of steel, until a specific deformation is obtained (ASTM D 36). The results of the softening point test are presented in Fig. 6.

Evaluation of polypropylene fibers addition on asphalt mixtures characteristics

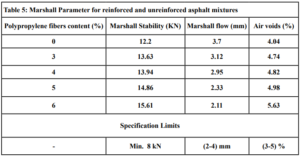

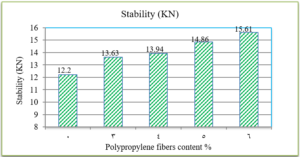

At this stage, 45 Marshall specimens are prepared using asphalt binder content (5%). The Marshall test results for reinforced and unreinforced asphalt mixtures are tabulated in Table 5.

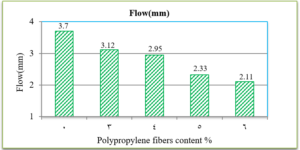

Fig. 8 indicates that as the Polypropylene fibers content increases, the Marshall flow for asphalt mixtures decreases.

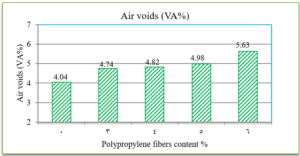

Fig. 9 presents the results of air voids percentage in the total mix for all mixtures. It indicates that polypropylene fibers have increased the air void percentage in all the specimens.

DISCUSSION

The penetration results indicate that the consistency of the PPF reinforced asphalt decreases as the PPF content in the mix increases. The reduction in penetration values were (29%, 38%, 51% and 62%) with the addition of (3%, 4%, 5% and 6%) of PPF, respectively, as compared to the unreinforced asphalt. This means that the addition of PPF makes the asphalt harder and more consistent. These results indicate that the rutting resistance of the mix is improved, but on the other hand, the high stiffness makes the asphalt concrete less resistant to fatigue cracking. It was also found in this research that the ductility values decreased as the addition percentage increased. This could be due to the position of polypropylene fibers in the cross-section of the asphalt binder during the ductility test, which prevents the asphalt from stretching easily. By increasing the Polypropylene fibers content, the softening point increased. This increase ranges from 16% to 36% with the addition of 3% to 6% of PPF content, this result indicates that the resistance of the reinforced asphalt binder to high temperatures is increased. Consequently, the results of the asphalt binder tests indicate that the reinforced asphalt samples with PPF are much stiffer and more resistant to high temperatures and rutting. The results of the Marshall tests indicate that the increasing in the polypropylene fibers content led to an increase in Marshall stability and decrease in flow values for asphalt mixtures. Increasing of 12%, 14%, 22% and 28% in stability values with the addition of 3%, 4%, 5% and 6% of PPF, respectively, to comparing with the traditional asphalt mixtures. Polypropylene fibers led to increase the air voids in all reinforced mixtures. This could have occurred because all the specimens were prepared 5% asphalt content, therefore, PPF added samples need more asphalt traditional specimens. However, the air voids of reinforced mixtures with Polypropylene fibers up to 5% content were acceptable as compared with the specification limits (3-5%) [ASTM].

CONCLUSIONS

Based on the results of studying the effect of polypropylene fibers in asphalt concrete mixtures, it can be deduced:

- The laboratory tests of asphalt binder showed that polypropylene fibers change the characteristics of original asphalt binders such as decreasing penetration at 25 °C, decreasing ductility and increasing softening points with the increasing of polypropylene fibers content. These results indicate that PPF reinforced asphalt can improve the characteristics of asphalt concrete against deformation, and we recommend to use it in high temperature areas.

- The results of the Marshall tests indicated that the addition of PPF led to increase the stability value and air voids content, while the flow values decreased.

- The recommended proportion of the polypropylene fibers (PPF) is 5% by weight of the asphalt binder.

RECOMMENDATIONS

- Study of the microstructure of the asphalt binder and mixture using Scanning Electron Microscopy (SEM).

- Study the behavior of polypropylene fiber reinforced asphalt mixtures on fatigue performance.

- Investigate the effect of other fibers (glass and carbon fibers) on the characteristics of asphalt binder and HMA mixtures.

References :

The Authors declare that they have no competing interests. Fund: No Fund

Competing Interests :

Author contributions: All the work was made by the author.

Data and materials availability: All data are available in the main text.

(ISSN - Online)

2959-8591