Future Prospects of Thermochemical Conversion Processes of Biomass

2023-04-18 | Volume 1 Issue 1 - Volume 1 | Review Articles | Rafat Al AfifAbstract

Producing green energy from renewable raw materials, organic waste and energy crops, will benefit society. Industrial biofuels might be sustainable and non-polluting if they are correctly integrated with the natural ecological cycles. In this context biomass thermal processing, torrefaction, hydrothermal conversion, pyrolysis, and gasification could convert bio-waste into sustainable energy feedstocks. This review aims to present what has been done on the thermochemical conversion of biomass, and what are the current challenges and future ideas. Bio-fuel production through hybrid renewable energy systems. Integrated renewable energy systems can increase energy storage capacity, reduce energy production costs, and improve the quality of generated power. More work should be done on the ways to maximize renewable sources fraction while minimizing the costs, real-life testing, as well as on combining these technologies with carbon capture and storage.

The list of abbreviations :

| HTC | Hydrothermal Carbonization |

| HTL | Hydrothermal Liquefaction |

| HTG | Hydrothermal Gasification |

| FT- synthesis | Fischer- Tropsch Synthesis |

| Bio- FT | bio- Fischer- Tropsch |

| DME | Dimethyl ether |

| HVO | Hydrogenated Vegetable Oil |

| HEFA | Hydroprocessed Esters and Fatty Acids |

| CSS | Carbon Capture and Storage |

Introduction

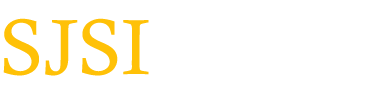

Due to rapid industrialization, urbanization, and population growth, the demand for energy and its resources is increasing annually. It is projected that global energy consumption will reach 812 quadrillion KJ in 2035, meanwhile, fossil fuels are still the dominant energy source. The use of petroleum and other liquid fossil fuels worldwide was 85.7 million barrels/day in 2008 and is expected to increase to 112.2 million barrels/day in 2035 (1). It is expected that we will deplete the entire global oil reserve by 2050 (2). Approximately 86% of global CO2 emission is associated with the use of fossil fuels with 2 billion tons year-1 discharged by coal-fired power plants as prevalent around the globe (3,4). Due to concerns over rising fuel prices, declining reserves of fossil fuels, and environmental issues such as pollution and global warming, a novel, sustainable approach to energy production is urgently needed. Biomass and fuels derived from its processing are one of promising alternatives to conventional fossil fuels (5). Sustainability, feedstock diversity, and low to no emissions of gasses such as soot, SO2, or NOx make biomass a promising energy source. However, treatment is needed for biomass to be converted into biofuels and chemicals that have ready use due to its high moisture and oxygen content and consequently lower energy-density compared to fossil fuels (6,7). According to Faaij (2006) research, bio-energy could meet current global energy needs with a potential of over 1000 EJ year-1 (8). Additionally, biofuels are carbon neutral as the CO2 released by their combustion is consumed again for the growth of other biomass via photosynthesis (1). Fig. 1 shows the conversion routes of biomass to bioenergy. Biogas, ethanol and biodiesel are examples of first-generation biofuels that are directly tied to biomass that is frequently edible (9–13). To make first-generation bioethanol, only a few distinct feedstocks are actually employed, namely sugarcane or corn. Brazil is one of the top countries using sugarcane as a feedstock for the manufacture of biofuels.

Fig. 1 Conversion of biomass to bioenergy

In the future, efficiency can be further improved through the development of superior crop varieties, improved crop management techniques, and advancements in ethanol production processes (8). The only other biofuel made on an industrial basis is biodiesel produced from oily plants and seeds and commonly used in Europe and Asia (14). There is a number of environmental and socioeconomic concerns around the first generation biofuels future perspective such as land use, food competitivness, and lifecycle (15). Moreover, the growth is dictated by biomass prices on the market. Some of these challenges are banished through newer generation fuels. Second generation biofuels utilize the range of different feedstocks such as non-edible lignocelulosic biomass, different residues and waste products such as bio-waste and municipal solid waste (14,16).

Thermochemical conversion

The most well-known method of converting biogenic waste is thermochemical conversion, which also includes pyrolysis, gasification, liquefaction, hydropyrolysis, and reforming (17–21). The biomass is transformed into hydrocarbons and synthesis gas through gasification, whereas pyrolysis and liquefaction directly transform the biomass at high temperatures into bio-oils, gases, and char.

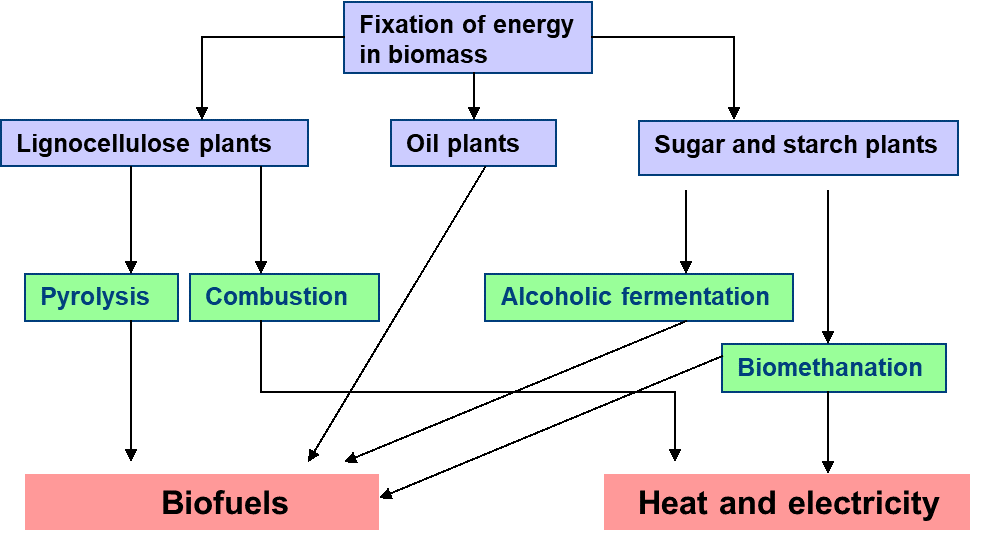

Hydrothermal process

Energy-denser product is derived from biomass via hydrothemal conversion.As the technology operates in an aques environment, no pre-drying of the feedstock is necessery and biomass with higher moisture content can be directly utilized (22). HTC yields solid fuel (hydrochar) under temperatures between 180–280 for 5–240 min (23). From 250°C to 375°C and pressure of 10–25 MPa HTL takes place producing bio-crude or crude-oil,which is a liquid fuel consisting of insoluable organics (24,25). Bio-crude requires only slight upgrading to be used commercially while by-products of liquifaction have lucrative applications (i.e. fertilizer). Possible future research areas include setting up a plant suitable for both wet and dry feedstock, analyzing the influence of various parameters, optimizing for better conversion, and developing theoretical models to accurately represent the process depending on the feedstock (26). Moreover, When biomass is heated to high temperatures during hydrothermal liquefaction above 375°C the process is known as HTG, macromolecules are broken down into molecules with smaller molecular weights, creating syngas see Fig.2

Fig.2 Hydrothermal process

Torrefaction

Torrefaction is a thermal conversion process used to pre-treat biomass converting it into a more uniform and energy dense product. Heating under inert atmosphere in the temperature range of 200-300°C enhances the fuel properties of biomass by improving combustion properties (27), homogenuity, physical and chemical properties making it similar to coal.The torrefied biomass is biologically stable, hydrophobic, and significantly lower in moisture content compared to raw feedstocks (28). It is expected that all traditional pelletisation facilities would transition to torreaction plants for the production of torrefied pellets. Furthermore, the biomass pre-treated like this is easier to handle and transport to locations where it can be applied for heating fuel, cofiring, gassification, etc. Optimisation of this technology is expected around combustor, heat exhangers, as well as nitrogen feed, while research is being conducted on techno-economical performance of the technology (7).

Pyrolysis

For the waste reduction of biomass conversion technologies entire carbon content of the feedstock should be converted into a valuable product (29). Pyrolysis distributes carbon atoms between biocrude, char, and syngas (30). Despite major success of recent engineering endovours on this topic (31), further research should be conducated on novel reactors with improved cost and overall effectiveness. Furthermore, intergeration with anaerobic digestion is a promissing future direction for higher quality bio-oil and solution of an environmental problem (29).

Gasification and biofuels

Gasification produces less toxic fuels compared to fossil that can use existing infrastructure. While commercial production of biofuels from gasification does not currently exist, there has been increasing interest and research on this approach over the past few decades. The gasification process produces syngas, a mixture of carbon monoxide and hydrogen, from biomass. This syngas then undergoes further chemical processing to produce fuels and chemicals that are readily available on the market as shown in Fig.3.

Fig. 3 Scheme of biofuels production through gasification

Through methanation synthesis gas is produced. FTS yields kerosene (jet fuel), disel, and gasoline liquid fuels. Several commercial-scale initiatives are currently in the works, especially in the United States but also in Europe and Japan, even though bio-FT is currently in the demonstration stage. The initiatives cover a wide range of end products and feedstock options. Even carbon capture and storage will be used in one project, the Bayou Fuels biorefinery in the United States, to create negative emissions, sometimes referred to as carbon dioxide reduction. Biojet kerosene has to make significant strides in order to align with the Net Zero Scenario by 2030. The success of biojet kerosene depends on reducing costs, implementing clear regulatory schemes and policies, and diversifying sustainable feedstock supplies beyond waste and edible oils. Synthesized methanol can be further upgraded into gasoline, DME (fuel additive), and polymers, as well as acetic acid and formaldehyde. Hydrogen that is produced in gasification process can be used directly as a fuel or to further synthesize ammonia and urea (8,32). According to IEA, these production pathways could enable renewable diesel and biojet kerosene to sustainably scale up to the levels necessary in the Net Zero Scenario as they utilize more abundant feedstock compared to some already commercially viable options such as HVO and HEFA (32). The equipment needed for these secondary processes is similar to that used for natural gas, but gas cleaning is more intensive. There have been some pilot projects demonstrating this approach, but technological challenges remain compared to other biofuel production methods. While current process technologies can be applied once clean syngas is available, further research and development are needed to improve gas-cleaning, scale up processes, and achieve higher efficiencies and lower costs through more advanced concepts like liquid phase methanol production and improved gas separation. Some countries are increasing interest and investment in research on advanced gasification for syngas production as a long-term strategy.

Hybrid Renewable System Technology

Another initiative to tackle energy challenges in a sustainable way is to adopt hybrid renewable energy systems. Such a setting that combines multiple renewable energy sources overcomes the issue of spatiotemporal variability of these resources. Compared to single resource-based energy generation systems, integrated renewable energy systems can increase energy storage capacity, reduce energy production costs, and improve the quality of generated power (33). Furthermore, such systems offer greater flexibility and promote overall socio-economic growth (34,35). Hybrid renewable systems incorporating thermal conversion of biomass with other renewable energy sources received considerable attention in research (35–39). For instance, Facchinetti et al. worked on the integration of a solid fuel cell-gas turbine cycle powered with hydrothermally converted biomass obtaining the efficiency of 63% (40). Heidari et al. performed hydrothermal carbonization of biomass. The hydrochar was used in the integrated system to produce power and process water in anaerobic digestion to obtain biogas later used as a gaseous fuel (41). On the other hand, biomass can be anaerobically digested to produce biogas that can be used to generate heat or electricity, while the digestate can be pyrolyzed in the integrated system to obtain gas, oil, and char. Deng at al. found that such a system could be self-sustaining by combusting pyrolytic gas and excess char. Another important aspect is the energy storage (42). Concepts such as Green to Green energy system aim to find a green storage system, such as fuel cell, for the green energy (43,44). Lin et al. proposed a plant for simultaneous generation of electricity and liquid hydrogen involving a lignocellulosic biomass gasification-integrated gas turbine and hydrogen liquefaction cycle with an electrolyzer process (45). Table 1 gives an overview of what other initiatives were taken on thermal conversion technology hybrid systems. However, study by Lee at al. showed that more research should be done on testing conceptually created models in real life conditions, addressing power fluctuation issues in the grid-connected system, removal of ash and moisture via pre-treatment technologies, etc (33).

Table 1: An overview of systems integrating thermochemical conversion of biomass with other renewable energy technologies

| Feedstock | System setting | Aim | Source | |

| Lignocellulosic biomass | Gasification concentrated solar thermal power | Electricity generation | (46) | |

| Fusion power gasification | Hydrocarbon fuel or hydrogen production | (47) | ||

| Adiabatic compressed air energy storage gasification | Electricity generation and energy storage | (48) | ||

| Bio-oil combustion – photovoltaics | Electricity generation | (49) | ||

| Anaerobic digestion – pyrolysis | Electricity generation and pyrolytic product production | (50) | ||

| Gasification – pyrolysis | Biochar production and electricity generation | (51) | ||

| Biomass combustion – biomass gasification – biomass pyrolysis photovoltaics – wind power vanadium redox battery-based energy storage system | ||||

| Seaweed/wood | Pyrolysis – anaerobic digestion | Methane production | (42) | |

| Wheat straw | Anaerobic digestion hydrothermal carbonization | Energy recovery | (52) | |

| Spent coffee ground | Hydrothermal carbonization – anaerobic digestion | Methane production | (41) |

Carbon capture and storage

IPCC’s Fourth Assessment Report highlighted that emissions must be diminished by 50-85% until 2050 to keep global warming below 2°C. Through IPCC’s Special Renewable Energy Sources and Climate Change Mitigation and Technology Roadmap Carbon Capture and Storage in Industrial Applications, bio-CCS was recognized as a single wide-reaching technology that could reach negative carbon footprint (53–55). It combines sustainable biomass conversion with CO2 Capture and Storage technology. For its growth, biomass absorbs CO2 from the atmosphere. Nevertheless, in conversion processes, CO2 is once more exhausted in the air. CCS technology aims to capture this exhaustion, deliver, and store it safely underground through natural mechanisms (residual, dissolution, and mineral trapping)(15).

The production of biofuels, such as ethanol fermentation and bio-FT, produces a high concentration of CO2 as a byproduct. As a result, these pathways have the potential to capture and utilize CO2 for storage or use. The cost of capture and transport is relatively low. Due to the high concentration of CO2 produced, no additional purification is required apart from dehydration. Once the CO2 is captured, it can be compressed and transported via pipeline, truck, or ship to a storage site or be used in some way. For example, captured CO2 has been sold for use in enhanced oil recovery or within the food and beverage sector. Researchers are exploring the potential of combining fossil fuels with sustainably grown biomass in flexible conversion facilities to produce fuels and other products. Gasification-based conversion platforms offer a flexible method for fuel production from biomass, coal, and natural gas. Combining sustainably grown biomass with (partial) CO2 capture allows for overall negative CO2 emissions per unit of energy produced on a life cycle basis. This approach can be used to produce hydrogen, where all carbon monoxide produced is shifted to hydrogen and CO2. A co-feeding strategy, such as with coal, can be attractive in the short term for organizing large-scale biomass supplies. When equipped with CO2 capture facilities, the input share of fossil fuel can still become “carbon neutral”. Negative emissions could be obtained by using more biomass. For instance, bio-CSS can be applied in large industrial operations where there is a local heat or power requirement, particularly in industrial clusters where CCS infrastructure can be shared. The use of biomass in the industry to replace fossil fuels has a variety of potential applications, including small and medium-scale heat and power, fuel substitution in cement kilns, and injection in blast furnace steel and iron-making. Existing large-scale gasification technology can be used to gasify biomass feedstock, which could be supplied as crude bio-oils obtained via pyrolysis or treated via torrefaction, reducing transport costs and facilitating feeding to pressurized gasification systems. Some exploratory work on large-scale and long-distance biomass supplies for large-scale syngas production has been done with promising results, indicating that this is a concept that deserves further study and development. European Technology Platform for Zero Emission Fossil Fuel Power Plants shows that an additional step further could be made by completely substituting fossil fuels and using bio-CSS in an independent bio-fuel production plant. Biomass is converted to char and gas in the gasifier. Char amounts for 6% of overall carbon content of the biomass. After gas treating, 52% of carbon content can be stored in CO2, while the remaining 42% are converted through FT- synthesis (15).

Conclusion

This review discusses the future of biomass conversion as a sustainable approach to energy production and carbon emissions reduction. It is an abundant and sustainable resource with the potential to reduce or entirely substitute fossil fuels. We explore different types of biofuels and conversion technologis specifically thermal conversion. Gasification is a promissing process to convert biomass into non-toxic fuels and useful chemicals while using existing infrastructure. For it to be applied on the industrial scale, further research on advanced tehniques is needed to improve gas cleaning and lower the costs of highly effective processes. Hybrid renewable energy systems incorporating thermochemical conversion are promising direction to tackle climate change and simultaniously overcome energy challenges in certain regions. However, more work should be done on the ways to maximize renewable sources fraction while minimizing the costs, real life testing, etc. Furthermore, carbon capture and storage technology combined with sustainable biofuels production could help achieve carbon negativity. International agencies such as IEA and UNIDO are highlighting the importance of scaling up such technologies in the near future and need for additional research in this direction so that Net Zero goals can be achieved.

References :Reference

- 1. Mohanty P, Pant KK, Mittal R. Hydrogen generation from biomass materials: challenges and opportunities. WIREs Energy Environ. 2015 Mar;4(2):139–55.

- Saxena RC, Adhikari DK, Goyal HB. Biomass-based energy fuel through biochemical routes: A review. Renew Sustain Energy Rev. 2009 Jan;13(1):167–78.

- Song C, Liu Q, Deng S, Li H, Kitamura Y. Cryogenic-based CO2 capture technologies: State-of-the-art developments and current challenges. Renew Sustain Energy Rev. 2019 Mar;101:265–78.

- Taipabu MI, Viswanathan K, Wu W, Hattu N, Atabani AE. A critical review of the hydrogen production from biomass-based feedstocks: Challenge, solution, and future prospect. Process Saf Environ Prot. 2022 Aug;164:384–407.

- Al Afif R, Pfeifer C, Pröll T. Bioenergy Recovery from Cotton Stalk. In: Ansari M ur R, editor. Advances in Cotton Research [Internet]. IntechOpen; 2020 [cited 2023 Feb 16]. Available from: https://www.intechopen.com/books/advances-in-cotton-research/bioenergy-recovery-from-cotton-stalk

- Fu J, Zhang Z, Ren Q. The Future of Biomass Utilization Technologies Special Issue Editorial. Ind Eng Chem Res. 2020 Sep 30;59(39):16895–8.

- Batidzirai B, Mignot APR, Schakel WB, Junginger HM, Faaij APC. Biomass torrefaction technology: Techno-economic status and future prospects. Energy. 2013 Dec;62:196–214.

- Faaij A. Modern Biomass Conversion Technologies. Mitig Adapt Strateg Glob Change. 2006 Mar;11(2):343–75.

- Afif RA, Pfeifer C. Biochemical methane potential of three-phase olive mill solid waste: Influence of temperature and supplemental enzymes. Carbon Resour Convers. 2022 Sep;5(3):248–54.

- Al Afif R, Pfeifer C. Enhancement of methane yield from cotton stalks by mechanical pre-treatment. Carbon Resour Convers. 2021;4:164–8.

- Al Afif R, Wendland M, Amon T, Pfeifer C. Supercritical carbon dioxide enhanced pre-treatment of cotton stalks for methane production. Energy. 2020 Mar;194:116903.

- Al Afif R, Linke B. Biogas production from three-phase olive mill solid waste in lab-scale continuously stirred tank reactor. Energy. 2019 Mar;171:1046–52.

- Al Afif R, Amon T. Mesophilic anaerobic co-digestion of cow manure with three-phase olive mill solid waste. Energy Sources Part Recovery Util Environ Eff. 2019 Aug 3;41(15):1800–8.

- Lee RA, Lavoie JM. From first- to third-generation biofuels: Challenges of producing a commodity from a biomass of increasing complexity. Anim Front. 2013 Apr 1;3(2):6–11.

- Biomass with CO2 Capture and Storage (Bio-CCS) [Internet]. European Technology Platform for Zero Emission Fossil Fuel Power Plants; Available from: https://www.etipbioenergy.eu/images/EBTP-ZEP-Report-Bio-CCS-The-Way-Forward.pdf

- Dou B, Zhang H, Song Y, Zhao L, Jiang B, He M, et al. Hydrogen production from the thermochemical conversion of biomass: issues and challenges. Sustain Energy Fuels. 2019;3(2):314–42.

- Nanda S, Mohanty P, Pant KK, Naik S, Kozinski JA, Dalai AK. Characterization of North American Lignocellulosic Biomass and Biochars in Terms of their Candidacy for Alternate Renewable Fuels. BioEnergy Res. 2013 Jun;6(2):663–77.

- Balat M. Production of bioethanol from lignocellulosic materials via the biochemical pathway: A review. Energy Convers Manag. 2011 Feb;52(2):858–75.

- Sukumaran RK, Surender VJ, Sindhu R, Binod P, Janu KU, Sajna KV, et al. Lignocellulosic ethanol in India: Prospects, challenges and feedstock availability. Bioresour Technol. 2010 Jul;101(13):4826–33.

- Ayala-Cortés A, Arcelus-Arrillaga P, Millan M, Arancibia-Bulnes CA, Valadés-Pelayo PJ, Villafán-Vidales HI. Solar integrated hydrothermal processes: A review. Renew Sustain Energy Rev. 2021 Apr;139:110575.

- Leng S, Leng L, Chen L, Chen J, Chen J, Zhou W. The effect of aqueous phase recirculation on hydrothermal liquefaction/carbonization of biomass: A review. Bioresour Technol. 2020 Dec;318:124081.

- Antero RVP, Alves ACF, de Oliveira SB, Ojala SA, Brum SS. Challenges and alternatives for the adequacy of hydrothermal carbonization of lignocellulosic biomass in cleaner production systems: A review. J Clean Prod. 2020 Apr;252:119899.

- Seyedsadr S, Al Afif R, Pfeifer C. Hydrothermal carbonization of agricultural residues: A case study of the farm residues -based biogas plants. Carbon Resour Convers. 2018 Apr;1(1):81–5.

- Ruiz HA, Galbe M, Garrote G, Ramirez-Gutierrez DM, Ximenes E, Sun SN, et al. Severity factor kinetic model as a strategic parameter of hydrothermal processing (steam explosion and liquid hot water) for biomass fractionation under biorefinery concept. Bioresour Technol. 2021 Dec;342:125961.

- Lachos-Perez D, César Torres-Mayanga P, Abaide ER, Zabot GL, De Castilhos F. Hydrothermal carbonization and Liquefaction: differences, progress, challenges, and opportunities. Bioresour Technol. 2022 Jan;343:126084.

- Gollakota ARK, Kishore N, Gu S. A review on hydrothermal liquefaction of biomass. Renew Sustain Energy Rev. 2018 Jan;81:1378–92.

- Bridgeman TG, Jones JM, Shield I, Williams PT. Torrefaction of reed canary grass, wheat straw and willow to enhance solid fuel qualities and combustion properties. Fuel. 2008 May;87(6):844–56.

- Khazraie Shoulaifar T, DeMartini N, Ivaska A, Fardim P, Hupa M. Measuring the concentration of carboxylic acid groups in torrefied spruce wood. Bioresour Technol. 2012 Nov;123:338–43.

- Vuppaladadiyam AK, Vuppaladadiyam SSV, Sahoo A, Murugavelh S, Anthony E, Bhaskar T, et al. Bio-oil and biochar from the pyrolytic conversion of biomass: A current and future perspective on the trade-off between economic, environmental, and technical indicators. Sci Total Environ. 2023 Jan;857:159155.

- Sahoo A, Kumar S, Kumar J, Bhaskar T. A detailed assessment of pyrolysis kinetics of invasive lignocellulosic biomasses (Prosopis juliflora and Lantana camara) by thermogravimetric analysis. Bioresour Technol. 2021 Jan;319:124060.

- Al Afif R, Anayah SS, Pfeifer C. Batch pyrolysis of cotton stalks for evaluation of biochar energy potential. Renew Energy [Internet]. Available from: https://www.sciencedirect.com/science/article/pii/S0960148119314909

- IEA (2022), Biofuels [Internet]. IEA; Available from: https://www.iea.org/reports/biofuels

- Lee J, Kim S, You S, Park YK. Bioenergy generation from thermochemical conversion of lignocellulosic biomass-based integrated renewable energy systems. Renew Sustain Energy Rev. 2023 May;178:113240.

- Chauhan A, Saini RP. Techno-economic feasibility study on Integrated Renewable Energy System for an isolated community of India. Renew Sustain Energy Rev. 2016 Jun;59:388–405.

- Al Afif R, Ayed Y, Maaitah ON. Feasibility and optimal sizing analysis of hybrid renewable energy systems: A case study of Al-Karak, Jordan. Renew Energy. 2023 Mar;204:229–49.

- Al-Najjar H, El-Khozondar HJ, Pfeifer C, Al Afif R. Hybrid grid-tie electrification analysis of bio-shared renewable energy systems for domestic application. Sustain Cities Soc. 2022 Feb;77:103538.

- Al-Najjar H, Pfeifer C, Al Afif R, J. El-Khozondar H. Estimated View of Renewable Resources as a Sustainable Electrical Energy Source, Case Study. Designs. 2020 Sep 8;4(3):32.

- Al-Najjar H, Pfeifer C, Al Afif R, El-Khozondar HJ. Performance Evaluation of a Hybrid Grid-Connected Photovoltaic Biogas-Generator Power System. Energies. 2022 Apr 26;15(9):3151.

- Lee J, Lin KYA, Jung S, Kwon EE. Hybrid renewable energy systems involving thermochemical conversion process for waste-to-energy strategy. Chem Eng J. 2023 Jan;452:139218.

- Facchinetti E, Gassner M, D’Amelio M, Marechal F, Favrat D. Process integration and optimization of a solid oxide fuel cell – Gas turbine hybrid cycle fueled with hydrothermally gasified waste biomass. Energy. 2012 May;41(1):408–19.

- Heidari M, Salaudeen S, Norouzi O, Acharya B, Dutta A. Numerical Comparison of a Combined Hydrothermal Carbonization and Anaerobic Digestion System with Direct Combustion of Biomass for Power Production. Processes. 2020 Jan 1;8(1):43.

- Deng C, Lin R, Kang X, Wu B, O’Shea R, Murphy JD. Improving gaseous biofuel yield from seaweed through a cascading circular bioenergy system integrating anaerobic digestion and pyrolysis. Renew Sustain Energy Rev. 2020 Aug;128:109895.

- Ramadan M. A review on coupling Green sources to Green storage (G2G): Case study on solar-hydrogen coupling. Int J Hydrog Energy. 2021 Aug;46(59):30547–58.

- Haddad A, Jaber H, Khaled M, Al Afif R, Ramadan M. An investigation on coupling fuel cell, wind turbine and PV as green to green system. Int J Hydrog Energy. 2022 Jul;S0360319922027409.

- Lin H, Wu X, Ayed H, Mouldi A, Abbas SZ, Ebrahimi-Moghadam A. A new biomass gasification driven hybrid system for power and liquid hydrogen cogeneration: Parametric study and multi-objective evolutionary optimization. Int J Hydrog Energy. 2022 Jul;47(62):26394–407.

- Tanaka Y, Mesfun S, Umeki K, Toffolo A, Tamaura Y, Yoshikawa K. Thermodynamic performance of a hybrid power generation system using biomass gasification and concentrated solar thermal processes. Appl Energy. 2015 Dec;160:664–72.

- Nam H, Mukai K, Konishi S, Nam K. Biomass gasification with high temperature heat and economic assessment of fusion-biomass hybrid system. Fusion Eng Des. 2019 Sep;146:1838–42.

- Diyoke C, Wu C. Thermodynamic analysis of hybrid adiabatic compressed air energy storage system and biomass gasification storage (A-CAES + BMGS) power system. Fuel. 2020 Jul;271:117572.

- Perkins G. Techno-economic comparison of the levelised cost of electricity generation from solar PV and battery storage with solar PV and combustion of bio-crude using fast pyrolysis of biomass. Energy Convers Manag. 2018 Sep;171:1573–88.

- Monlau F, Sambusiti C, Antoniou N, Barakat A, Zabaniotou A. A new concept for enhancing energy recovery from agricultural residues by coupling anaerobic digestion and pyrolysis process. Appl Energy. 2015 Jun;148:32–8.

- Li L, Yao Z, You S, Wang CH, Chong C, Wang X. Optimal design of negative emission hybrid renewable energy systems with biochar production. Appl Energy. 2019 Jun;243:233–49.

- Reza MT, Werner M, Pohl M, Mumme J. Evaluation of Integrated Anaerobic Digestion and Hydrothermal Carbonization for Bioenergy Production. J Vis Exp. 2014 Jun 15;(88):51734.

- Edenhofer O, Pichs Madruga R, Sokona Y, IPCC, editors. Renewable energy sources and climate change mitigation: summary for policymakers and technical summary. Genf: International Panel of Climate Change; 2011. 230 p.

- Technology Roadmap Carbon Capture and Storage in Industrial Applications [Internet]. UNIDO, IEA; 2011. Available from: https://www.unido.org/sites/default/files/2011-09/CCS_Industry_Roadmap_WEB_2.pdf

- Schaffer S, Pröll T, Al Afif R, Pfeifer C. A mass- and energy balance-based process modelling study for the pyrolysis of cotton stalks with char utilization for sustainable soil enhancement and carbon storage. Biomass Bioenergy. 2019 Jan;120:281–90.

Competing Interests :

The authors declare that they have no competing interests.

(ISSN - Online)

2959-8591